Selecting Scaffolding Products: Steel vs. Aluminium

From Planning to Dismantling: The Scaffolding Lifecycle

Handling the scaffolding lifecycle includes cautious preparation, spending plan appropriation, and compliance with security policies. Design and design focus on architectural security and safety and security requirements. Efficient product procurement and assembly need attention to information and adherence to safety methods. Inspection and maintenance warranty compliance with security requirements, protecting against costly repairs. The taking apart process requires complete security precautions and proper waste administration practices. Additionally, examining recyclable products and reusing elements add to economical use and sustainability. Understanding these phases is critical for guaranteeing performance and safety and security in scaffolding jobs.

Planning Stage

Throughout the drawing board of the scaffolding lifecycle, meticulous focus to information is important to assure the success of the task. Pre building sychronisation plays an essential function in this phase, where all aspects of the scaffolding job are meticulously considered and arranged prior to any kind of physical work starts. This coordination includes liaising with various stakeholders, consisting of job managers, engineers, and vendors, to secure seamless integration and interaction throughout the project.

Among the vital jobs during the drawing board is budget plan allowance. Establishing a practical budget is essential to stop price overruns and hold-ups during the building and construction stage. By properly estimating the expenses of materials, labor, devices, and various other sources needed for the scaffolding task, job supervisors can guarantee that the job stays within spending plan restrictions.

Efficient planning at this stage lays the foundation for a successful scaffolding job, offering a roadmap for the subsequent phases of style, design, construction, and dismantling. By adhering to thorough planning methods and assigning resources wisely, task teams can alleviate threats and optimize task results.

Design and Engineering

The process of design and engineering in the scaffolding lifecycle is essential for ensuring architectural stability and security conformity throughout the job. When developing scaffolding, architectural stability is a primary problem. Designers should take into consideration elements such as the elevation of the structure, the weight it will certainly birth, and environmental conditions that might impact its security. Calculations for tons capacity are crucial to identify the scaffolding's ability to sustain workers, devices, and products safely.

Style and design also play an essential duty in making sure that the scaffolding fulfills all relevant security criteria and guidelines. By carefully preparing the layout and materials utilized, engineers can lessen risks of crashes and make certain a safe workplace for all employees involved. Furthermore, the design stage involves developing in-depth drawings and plans that guide the building procedure, making certain that the last framework satisfies the needed specifications.

Product Procurement

Reliable purchase of materials is essential for the successful implementation of scaffolding jobs. Establishing strong supplier relationships is crucial in making certain the timely distribution of high quality materials. By functioning carefully with suppliers, scaffolding firms can simplify their procurement procedures, reduce lead times, and address any material quality concerns immediately. Preserving open communication channels with distributors additionally permits better price monitoring, as it makes it possible for companies to negotiate desirable pricing contracts and secure price cuts for bulk acquisitions.

Expense management plays a significant function in product purchase, as it straight impacts the total project budget. Scaffolding firms have to carefully assess their material requirements, compare costs from different providers, and look for affordable options without jeopardizing on high quality and safety and security criteria. Carrying out efficient expense management strategies can help reduce project expenses and improve revenue margins. By prioritizing solid supplier relationships and efficient expense management methods, scaffolding firms can boost the efficiency and success of their tasks from the outset.

Assembly and Erection

For successful scaffolding projects, careful interest to detail during the assembly and erection process is important. Safety procedures have to be strictly stuck to in order to guarantee the wellness of workers and the overall success of the task. Prior to any kind of setting up begins, an extensive evaluation of the site must be performed to determine any type of potential threats or obstacles that might affect the erection procedure.

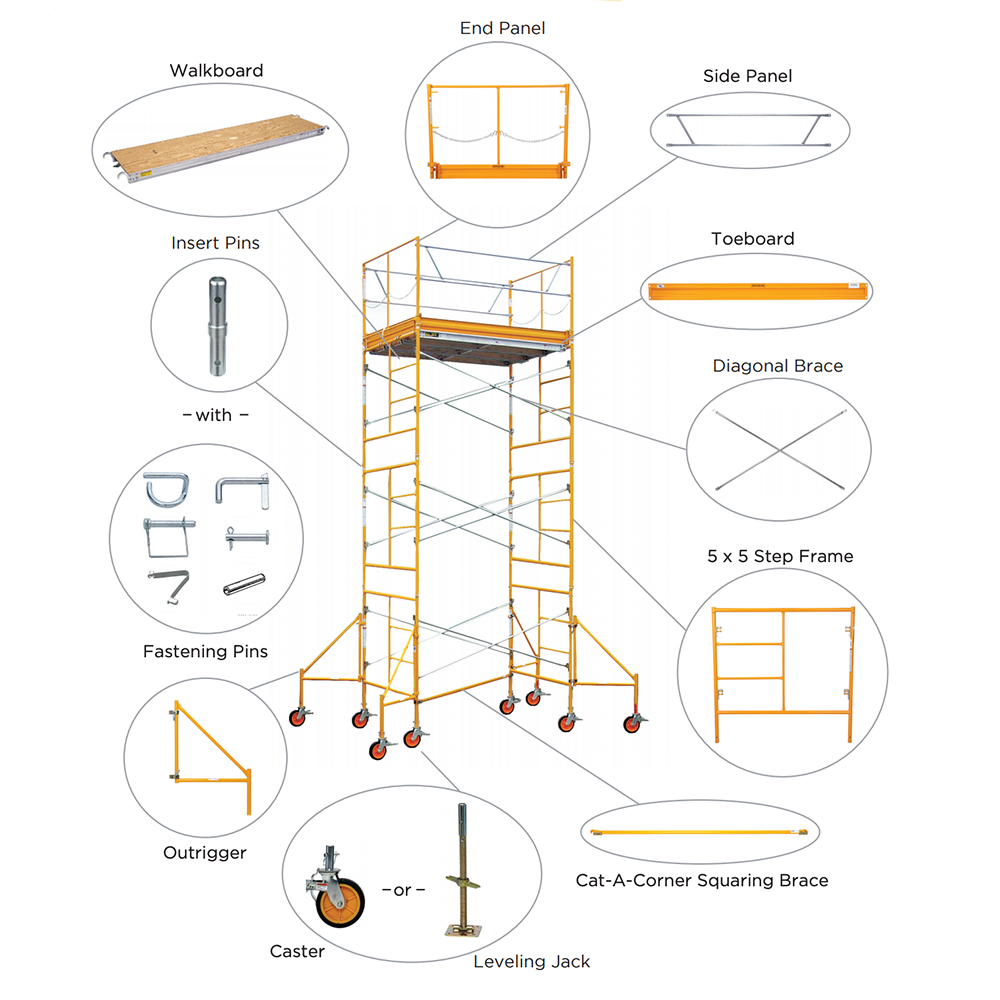

When it concerns erection techniques, it is necessary to follow producer guidelines and market finest techniques. Each component has to be safely secured, and the framework needs to be evaluated at different stages of the erection procedure to make certain stability and honesty. Appropriate sequencing of erection actions is important to stop any type of structural failings or mishaps. Additionally, making use of appropriate tools and equipment, along with trained personnel, is important for the safe and efficient setting up of the scaffolding.

Examination and Maintenance

Including an organized strategy to examination and maintenance is essential for guaranteeing the long life and safety and security of scaffolding frameworks. Safety checks play a vital role in recognizing any type of possible threats or issues that might jeopardize the security of the scaffolding.

Regular assessments should be performed by qualified personnel to verify that the scaffolding is in conformity with security policies and criteria. Preventative maintenance is just as crucial to attend to any wear and tear, deterioration, or damages that may happen throughout the scaffolding's usage. This proactive strategy can help stop mishaps and ensure the structural honesty of the scaffolding.

Applying an upkeep schedule that includes normal cleaning, lubrication of moving components, and architectural supports when necessary can dramatically prolong the life expectancy of the scaffolding. By focusing on safety checks and preventative upkeep, building firms can promote a secure working environment and stay clear of pricey repair services or replacements as a result of overlook or oversight.

Dismantling Process

The taking down procedure of scaffolding includes essential security preventative measures to guarantee the wellness of employees and onlookers.

Furthermore, the correct disposal of taken apart parts is essential to keep a tidy and organized workspace. https://hamptonhillscaffolding.co.uk

Security Safety Measures Throughout Taking Apart

Throughout the taking apart procedure of scaffolding, focusing on safety measures is important to avoid accidents and keep a smooth operations. Safety and security protocols should be purely adhered to throughout this phase to ensure the health of employees and the surrounding atmosphere. Correct training on taking down treatments, including equipment removal techniques, need to be provided to all employees entailed.

Prior to starting taking down, a detailed examination of the scaffolding structure must be conducted to determine any type of possible dangers or issues that might endanger safety. Additionally, using suitable personal protective equipment (PPE) such as headgears, handwear covers, and harnesses is vital.

Disposal of Dismantled Components

To preserve a risk-free and organized setting, the appropriate disposal of taken apart parts after completing the taking apart process of scaffolding is essential. Waste monitoring plays a crucial role in this stage, guaranteeing that materials are dealt with sensibly.

When thinking about disposal options, reusing is a vital selection that can help in reducing the environmental effect of building tasks. By setting apart materials like steel elements, wood planks, and other recyclable items, scaffolding business can add to minimizing waste sent to garbage dumps.

Additionally, discovering reusing choices for materials such as steel and light weight aluminum can not only benefit the setting but likewise possibly offer cost financial savings by repurposing these products for future tasks.

Appropriate waste management practices are essential to completing the scaffolding lifecycle sensibly.

Inspection After Dismantling

Upon finishing the taking down process of scaffolding, a thorough examination is conducted to assess the structural integrity and security of the components. This post-dismantling analysis is essential to confirm that the scaffolding parts are in excellent condition and risk-free for future usage.

Throughout the evaluation, each part is carefully examined for any indicators of damage, wear, or defects that may have taken place throughout the taking down process. Elements that pass the examination can be considered for reuse in future tasks, thus making best use of the cost-effectiveness of the scaffolding materials.

Regularly Asked Inquiries

How Does Climate and Environmental Aspects Impact the Scaffolding Lifecycle?

Weather condition sturdiness is important in the scaffolding lifecycle, as extreme conditions can speed up wear. Ecological factors like dampness and UV exposure additionally influence long life, increasing upkeep demands. Correct disposal of materials at the end of the lifecycle is essential for sustainability.

What Are Some Typical Obstacles Faced During the Taking Down Process of Scaffolding?

Difficulties experienced during the taking apart procedure of scaffolding include making sure safety and security, appropriate handling of materials, and evaluating components for reuse. Optimizing reusability needs careful planning, proficient labor, and adherence to safety procedures.

Are There Any Kind Of Particular Laws or Standards Pertaining To the Disposal of Scaffolding Products?

Disposal guidelines for scaffolding products are important to guarantee environmental compliance and safety. Several jurisdictions have details guidelines for correct disposal, advertising reusing alternatives whenever possible to lessen waste and promote sustainability in the building sector.

Exactly How Do Precaution Differ Throughout the Examination and Upkeep of Existing Scaffolding Frameworks Contrasted to Freshly Set Up Ones?

Safety and security methods during evaluation and upkeep of existing scaffolding frameworks concentrate on assessing wear, tear, and tons capability to guarantee ongoing safety and security. Unlike new scaffolds, upkeep procedures involve evaluating architectural stability and attending to potential hazards quickly.

Can Scaffolding Be Reused for Future Projects, and What Elements Identify Its Reusability?

Scaffolding sustainability is enhanced by considering reusability variables. Factors like worldly top quality, inspections, and adherence to policies influence whether scaffolding can be repurposed for future jobs, optimizing sources and advertising environmental responsibility in building practices.

Final thought

To summarize, the scaffolding lifecycle includes precise preparation, layout, material procurement, setting up, inspection, upkeep, and taking down. Each phase is important for guaranteeing the safety and security and performance of the structure.

By adhering to a methodical method throughout, construction projects can benefit from the assistance and stability offered by scaffolding. Appropriate taking down at the end of the project ensures the safe removal of the structure and lessens any kind of potential dangers.